Whatsapp: +8615936220108

Email: [email protected]

Whatsapp: +8615936220108

Email: [email protected]

News

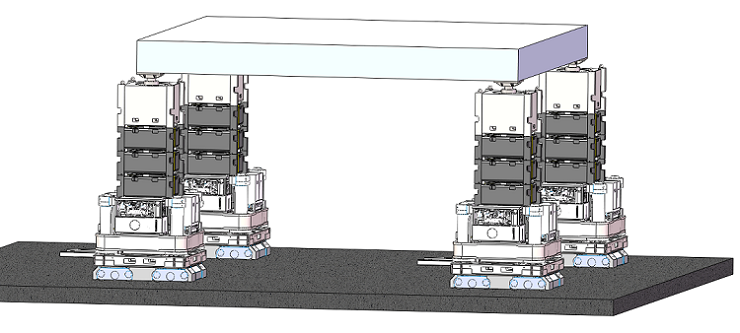

Lifting system

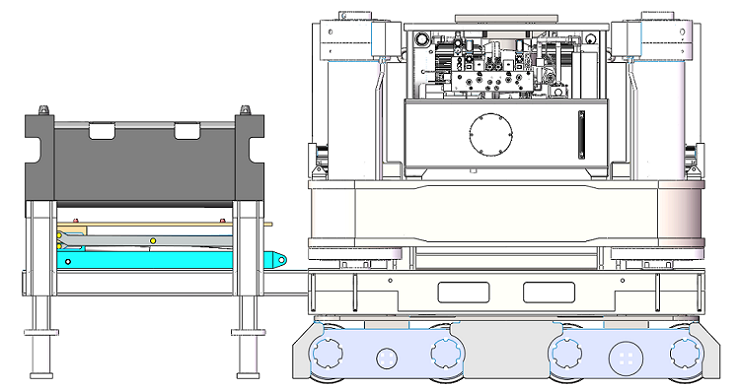

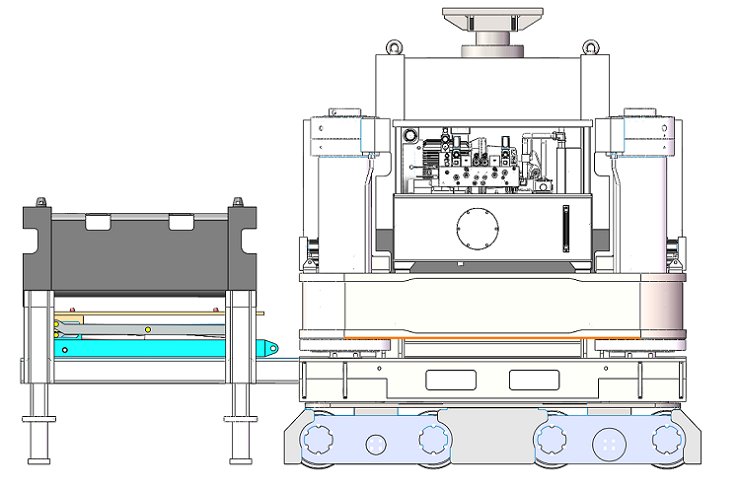

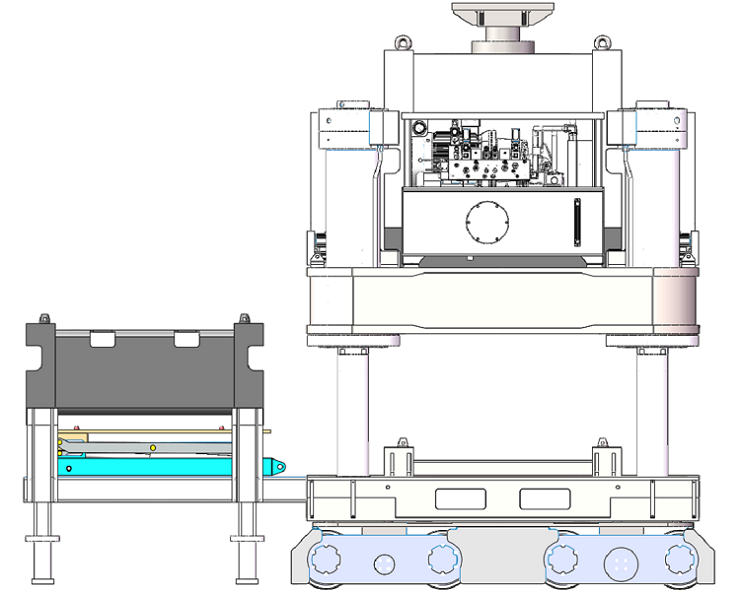

The 1000t modular jack up machine is composed of four groups of JLDS300 type jacking machines, four groups of simultaneous jacking to lift the load.

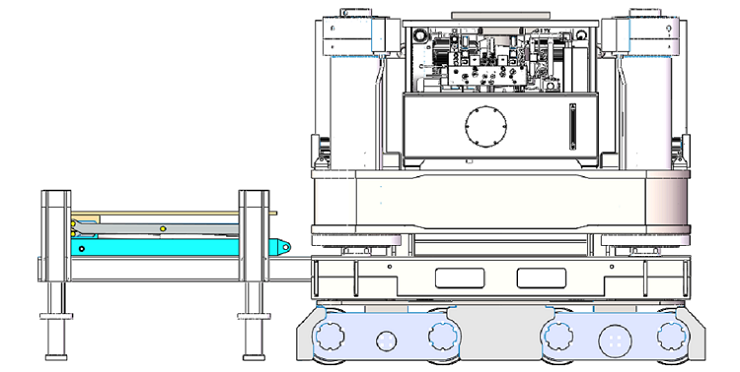

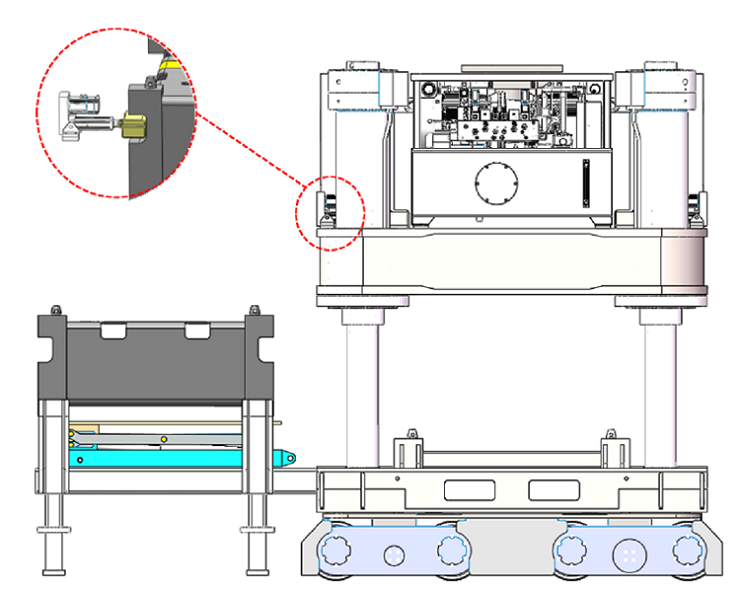

1)Connect the standard section introduction system with the basic section base by bolts;the trolley track needs to be kept in the same plane with the trolley on the base.

2)Lift and place the standard section on the four positioning, bracket by means of an auxiliary crane;

3)Operate the electric cylinder:

Push the pin into the groove of the top section.

The pin fits tightly with the vertical surface and arc surface of the groove of the top section. The four lifting cylinders lift the top frame. At this time, the top section is lifted, and space is reserved to introduce the standard section.

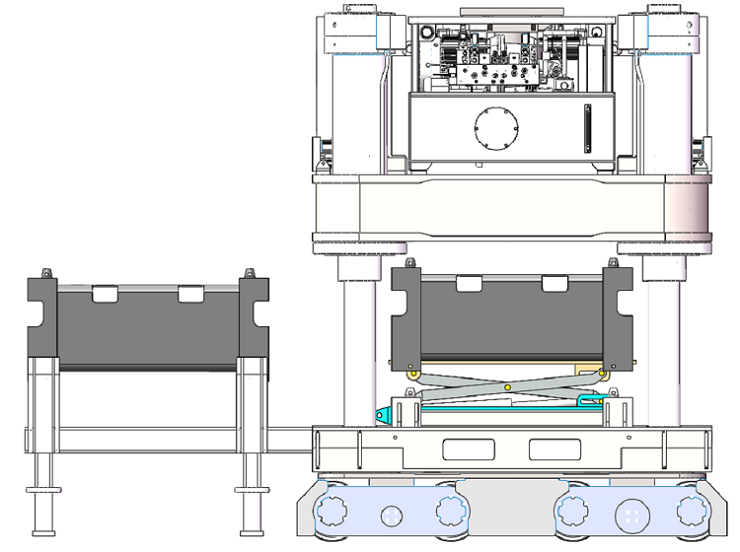

4)Operate the introduction system of the heightening device up to lift the standard section, the introduction of the trolley on the cover plate of the four positioning pins inserted into the standard section of the four holes in the lower cover plate, to prevent the standard section of the horizontal scurrying. Start the introduction trolley and slowly introduce the standard section under the top frame until the four pin holes in the main chord of the standard section and the base pin are aligned with each other.

5)Operation of the height-adjusting device down, slowly the standard section down, until the standard section falls to the base of the four convex platform, continue to height-adjusting device down, at this time, the trolley on the cover plate locating pins do not interfere with the standard section of the lower cover plate, operation of the introduction of the trolley to exit, until it returns to the introduction of the initial position of the bracket, to start the next introduction of the standard section.

6) Operate the four jacking cylinders to slowly until the top section main chord falls on the standard section main chord.

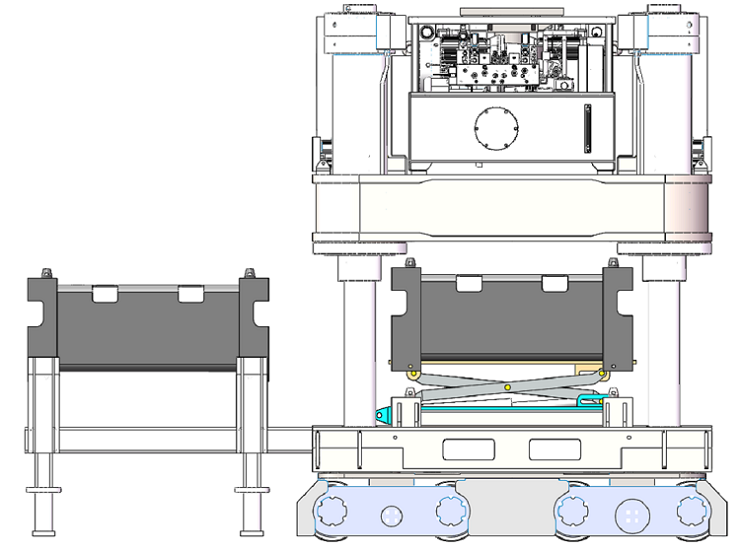

7) Operate the electric cylinder of the pin device to withdraw the pin from the groove of the top section, confirm that the pin is completely detached from the main chord of the top section, operate the four jacking cylinders to synchronize, continue to operate the electric cylinder of the pin device to push the pin into the groove of the standard section, confirm that the pin is tightly adhered to the façade and curved surface of the groove of the standard section, and operate the four jacking cylinders to synchronize the jacking of the top frame, and thus complete the process of introduction of a standard section. This completes the process of introducing a standard section. Refer to 4)-7) above for subsequent standard section raising operations.

We are here to help you

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.

Email: [email protected]

Phone / Whatsapp: +8615936220108

/ Company NewsApr 20, 2025

Youthful & Promising! School of Mechanical Engineering visit Jinli Heavy Industry for internship.

/ NewsJan 22, 2025

Jinli Crane 2024 Annual Summarization and Commendation MeetingOur professional team will reply you as soon as possible.

Submit Request

PDF Request

Simply fill out the form below and the catalog will be available for download!