Whatsapp: +8615936220108

Email: [email protected]

Whatsapp: +8615936220108

Email: [email protected]

News

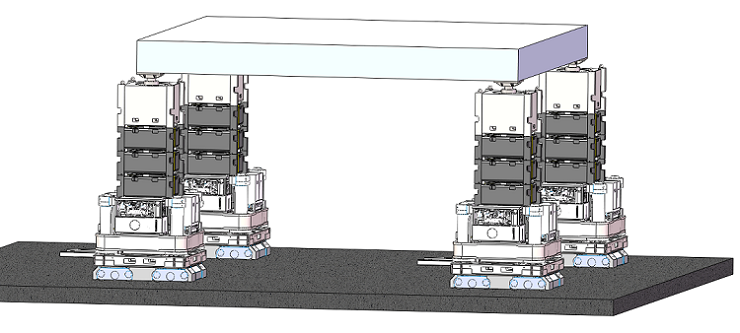

Jinli’s Hydraulic Modular Push-Up System provides customized and intelligent synchronized lifting solutions for industries such as construction, energy, transportation, and shipbuilding.

It overcomes space and load limitations, and is ideal for:

Lifting heavy equipment

Installing modular structures

Positioning large prefabricated components

Our experienced engineering team offers full planning and execution support for complex lifting operations.

Advantage | Technical Highlights | Supporting Tech |

| Modular Design | ▶ Scalable from 1 to 24 modules ▶ Rapid deployment in 72 hours (60% faster than traditional systems) | Patent pending: CN202410493488.X |

| Precision Sync | ▶ ±0.5mm accuracy with EPC control ▶ Auto-tilt compensation ▶ Mobile operation | Closed-loop hydraulic servo control |

| Extreme Conditions | ▶Stable performance (-30°C to 40°C) ▶Dust/moisture resistance | Sealed hydraulic cylinders |

| Safety Redundancy | ▶ Triple safeguards: - Real-time load monitoring (110% alert) - Mechanical auto-lock - Emergency manual override | Certified heavy equipment manufacturer |

Infrastructure: heavy lifting push up

Project Case:

Solution: Multi-point distributed lifting with synchronized control

1,200-ton heavy lifting

Push up machine used in other Sectors:

Power plant equipment (turbines/generators)

Wind turbine/wind tower foundation installation

Shipyard hull support & adjustment

Petrochemical tank/column positioning

How It Works

Our system operates on hydraulic-driven modular synergy:

Independent Modules: Each unit has dedicated hydraulic cylinders and controls.

Centralized Power: Hydraulic pump station enables smooth lifting/lowering.

Multi-Point Coordination: Ideal for confined spaces or load-distributed projects.

Design & Advantages

Structural Integrity

High-strength steel frame + sealed hydraulics

Adjustable legs/contact pads for uneven surfaces

RMC sync control ensures ±0.5mm precision

Core Benefits

✔ Modular Flexibility: Rapid assembly/disassembly for transport

✔ High Capacity: 125–800 tons per module

✔ Precision Control: Sensor-guided, shock-free movement

✔ Multi-Point Sync: 4/6/8+ module coordination

✔ Fail-Safe Mechanisms: Pressure limits, auto-locking, emergency protocols

Ideal Projects for Self-Lifting Systems:

Power plant equipment installation:

Generators & turbine positioning

Large modular assembly:

Precast bridge decks, wind turbine foundations, prefab structures

Precision chemical equipment handling:

Towers, tanks, reactors

Shipyard operations:

Hull support & alignment

Heavy machinery maintenance:

Foundation leveling & realignment

We are here to help you

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.

Email: [email protected]

Phone / Whatsapp: +8615936220108

Our professional team will reply you as soon as possible.

Submit Request

PDF Request

Simply fill out the form below and the catalog will be available for download!